API 20E: A Key Standard In The Petrochemical Industry

In the petrochemical industry, API 20E is a crucial standard for fasteners, playing a vital role in ensuring the quality and performance of fasteners. This standard covers multiple aspects including material selection, manufacturing processes, and product inspection, providing strict guidelines for the industry.

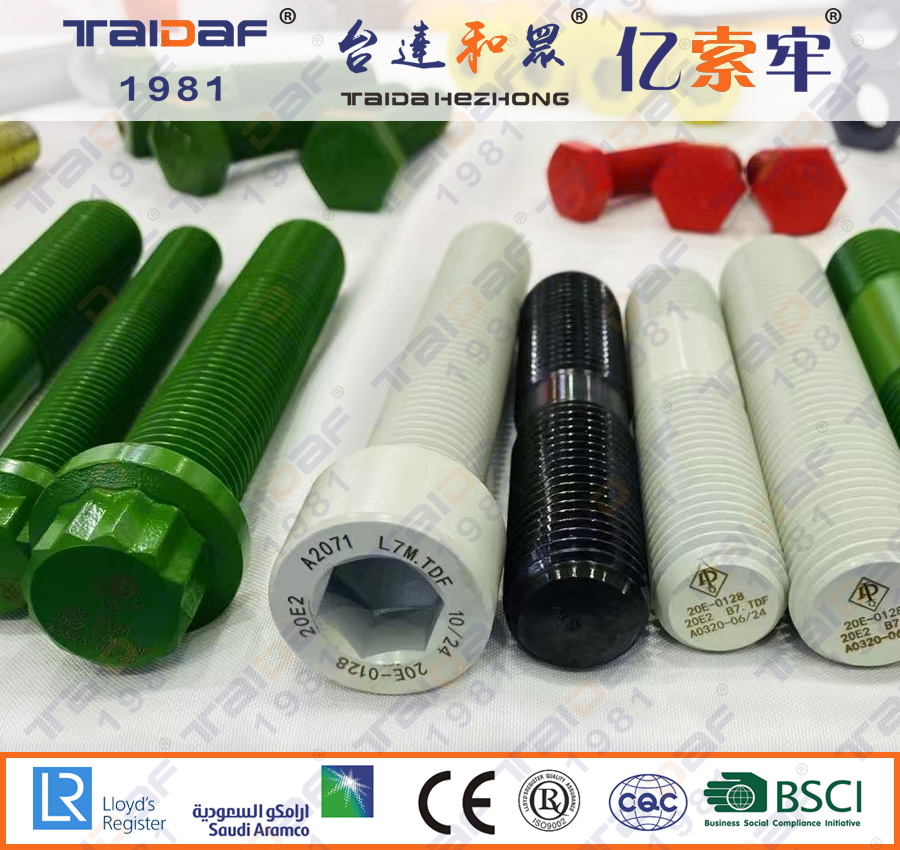

Ningbo Taida Fastener Manufacturing Co., Ltd. has always placed great emphasis on the API 20E standard. The company strictly adheres to this standard during the production process, closely monitoring every step from raw material procurement to processing.

In terms of materials, the company selects high - quality steel that meets the API 20E standard, ensuring that fasteners have excellent strength and corrosion resistance. Through advanced processing techniques, the products achieve high - level standards in terms of dimensional accuracy and surface quality.

The company's quality control system operates in strict accordance with the API 20E standard. Professional testing equipment and methods are used to conduct comprehensive inspections and tests on products, ensuring that every fastener meets the standard. For example, the mechanical properties and chemical composition of products are strictly tested to guarantee the product's ability to withstand various complex working conditions.

In terms of technological innovation, the company continuously invests in research and development to improve product performance and quality. By collaborating with well - known domestic and international research institutions and enterprises, it introduces advanced technologies and concepts to enhance product competitiveness.

For customers, choosing Ningbo Taida Fastener Manufacturing Co., Ltd. means obtaining products that meet the API 20E standard, with high quality and reliability. The company's products are not only competitive in the domestic market but also exported to many countries and regions overseas. The company has won wide recognition from customers with its excellent quality and good reputation.

In conclusion, the API 20E standard brings significant advantages to Ningbo Taida Fastener Manufacturing Co., Ltd. The company has outstanding performance in technological innovation, product quality, and service level, making it a reliable partner for customers. In the future, Ningbo Taida Fastener Manufacturing Co., Ltd. will continue to uphold the concept of innovation, development, and win - win, constantly improve its competitiveness, and provide more high - quality products and services to customers.

Production levels include: 6.8, 8.8, 10.9, 12.9, 10.9HV, 10.9HR, 8.8HR, B7, B7M, B16, L7, L7M, L4 3, B 8, B8 M, 660A \ B \ C \ D, N4400, 410, 420, 600, 625, 655, 665, 718, 2205, 2507, F51, F53, C276, 17-4, 825, 925, N08020

Production range: Diameter M12~M100 (1/2 "~4"); Bolt length 25-200mm; The length of the tooth strip is 55-8800mm.

01

High Quality

The company has advanced production and inspection equipment, participates in the formulation of several international standards, and has abundant technical strength. It has won 5 national invention patents and 15 national utility model patents.

02

Advanced Equipment

The company has the most advanced automated stereoscopic warehouse storage system and 20tons - level AGV intelligent handling robots for fastener industry in Ningbo area.

03

Professional Team

The company has its own R & D team and several senior technical and quality management personnel.

04

Custom Service

Our company has complete production & testing equipment. Can develop and produce products according to the drawings or samples provided by customers

The main equipment includes: 4 heat treatment Lines such as 80 meter long multi roll furnace, No. 6 mesh belt furnace, induction furnace and other heat treatment equipments; a robot - automatic hot forging bolt production machine; 21 full - automatic thread rolling machines; 3 multi - station cold forging machines; 9 chamfering - stamping machines; 1 dedicated production line for windpower anchor bolts; 3 turning - milling compound machines; 1 model - 100 peeling machine; 1 model - 40 peeling machine; 1 model - 100 straightening and calendering machine. The inspection equipment includes: 200 tons and 100 tons tensile strength testing machines; a fully automatic impact testing machines; an ultrasonic flaw detector; a magnetic particle flaw detectors; an eddy current flaw detector; 3 hardness test machines; a torque testing machine; a transverse vibration testing machine; a German Spectro desktop spectrometer; an American Niton handheld spectrometer; a projector; a metallographic analysis microscope, and other advanced laboratory equipment and dedicated vacuum-tight chamber .

We can provide a variety of fasteners, in line with national standards, the Ministry of Chemical Industry standards, the United States ASTM standards

Complete certificate: API-20E, API-20F, NORSOK M650/ISO17782,TUV Nande CE certification, TUV Nande AD2000 certification,ISO9001, ISO14001, ISO45001, to meet the needs of customers in many fields.

Diameter M12~M100 (1/2 "~4"); Bolt length 25-200mm; The length of the tooth strip is 55-8800mm.

During the development process, the company has always focused on the construction and improvement of the quality management system.

200 ton and 100 ton tensile strength testing

fully automatic impact testing machines

hardness machines

Magnetic particle testing machine permeation chamber