|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

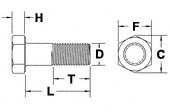

| Bolt Diameter | D | F | C | H | |||||

|---|---|---|---|---|---|---|---|---|---|

| Body Diameter | Width Across Flats | Width Across Corners | Height | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Dimensions per ASME B18.2.1 1996

|

TYPE 1

|

Medium carbon, carbon boron, or medium carbon alloy steel.

|

|

TYPE 2

|

Withdrawn November 1991.

|

|

TYPE 3

|

Weathering steel.

|

|

|

|

|

T

|

Fully threaded A325. (Restricted to 4 times the diameter in length)

|

|

M

|

Metric A325.

|

Connection Types

|

Size

|

Tensile, ksi

|

Yield, ksi

|

Elong. %, min

|

RA %, min

|

|

1/2 - 1

|

120 min

|

92 min

|

14

|

35

|

|

1-1/8 - 1-1/2

|

105 min

|

81 min

|

14

|

35

|

|

Nuts

|

Washers

|

|||

|

Type 1

|

Type 3

|

Type 1

|

Type 3

|

|

|

Plain

|

Galvanized

|

Plain

|

||

|

A563C, C3, D, DH, DH3

|

A563DH

|

A563C3, DH3

|

F436-1

|

F436-3

|

|

Note: Nuts conforming to A194 Grade 2H are a suitable substitute for use with A325 heavy hex structural bolts. The ASTM A563 Nut

|

||||

Production levels include: 6.8, 8.8, 10.9, 12.9, 10.9HV, 10.9HR, 8.8HR, B7, B7M, B16, L7, L7M, L4 3, B 8, B8 M, 660A \ B \ C \ D, N4400, 410, 420, 600, 625, 655, 665, 718, 2205, 2507, F51, F53, C276, 17-4, 825, 925, N08020

Production range: Diameter M12~M100 (1/2 "~4"); Bolt length 25-200mm; The length of the tooth strip is 55-8800mm.

01

High Quality

The company has advanced production and inspection equipment, participates in the formulation of several international standards, and has abundant technical strength. It has won 5 national invention patents and 15 national utility model patents.

02

Advanced Equipment

The company has the most advanced automated stereoscopic warehouse storage system and 20tons - level AGV intelligent handling robots for fastener industry in Ningbo area.

03

Professional Team

The company has its own R & D team and several senior technical and quality management personnel.

04

Custom Service

Our company has complete production & testing equipment. Can develop and produce products according to the drawings or samples provided by customers

The main equipment includes: 4 heat treatment Lines such as 80 meter long multi roll furnace, No. 6 mesh belt furnace, induction furnace and other heat treatment equipments; a robot - automatic hot forging bolt production machine; 21 full - automatic thread rolling machines; 3 multi - station cold forging machines; 9 chamfering - stamping machines; 1 dedicated production line for windpower anchor bolts; 3 turning - milling compound machines; 1 model - 100 peeling machine; 1 model - 40 peeling machine; 1 model - 100 straightening and calendering machine. The inspection equipment includes: 200 tons and 100 tons tensile strength testing machines; a fully automatic impact testing machines; an ultrasonic flaw detector; a magnetic particle flaw detectors; an eddy current flaw detector; 3 hardness test machines; a torque testing machine; a transverse vibration testing machine; a German Spectro desktop spectrometer; an American Niton handheld spectrometer; a projector; a metallographic analysis microscope, and other advanced laboratory equipment and dedicated vacuum-tight chamber .

We can provide a variety of fasteners, in line with national standards, the Ministry of Chemical Industry standards, the United States ASTM standards

Complete certificate: API-20E, API-20F, NORSOK M650/ISO17782,TUV Nande CE certification, TUV Nande AD2000 certification,ISO9001, ISO14001, ISO45001, to meet the needs of customers in many fields.

Diameter M12~M100 (1/2 "~4"); Bolt length 25-200mm; The length of the tooth strip is 55-8800mm.

During the development process, the company has always focused on the construction and improvement of the quality management system.

200 ton and 100 ton tensile strength testing

fully automatic impact testing machines

hardness machines

Magnetic particle testing machine permeation chamber